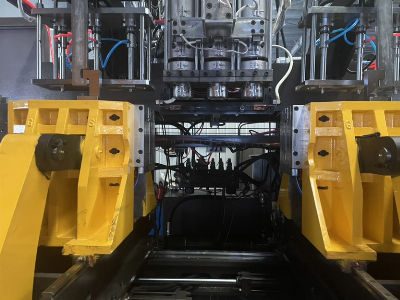

Product DescriptionGS-12L-II double station machine is different from the single station machine in that it has one additional station with high-precision linear guide. The same as the single station machines, it can be used to produce a wide variety of materials, such as PE, PP, etc. The largest capacity of the product can be 12L, and its production capacity is 60 to 70% more than the single station machine. In accordance with different type of products, die heads can be changed to achieve multi-type production. Setting:Clamping: Double station +High-precision guide +large arm cylinder axle Extrusion system: Hard gear surface reducer +Japan inverter Die system: Central-incoming extrusion die with special steel Hydraulic system: Japan hydraulic valve seal and proportional control Control system: Japan PLC +Imported HMI+PLC automatic 1. The maximum blow volume is 12L, PE, PP, EVA , TPU, etc. can be used.2. Taiwan DELTA servo system, could save energy consumption 20% for option3. Different screws and die mandrels, channel styles will be designed based on the specifics of different plastics;4, It is convenience to refueling, change color, purge, disassembly and cleaning with those die head. Symmetry part of the wall thickness is very uniform; 5, Double proportional valve control oil flow and pressure, directional valve control flow way, deceleration valve brakes, achieve smooth and fast action;6, Clamping mold is achieved with scissor toggle mechanism, mold carriage is with high-precision linear railway guide, every part of template bears the similar clamping force,7, Extruder platform can be lifted, easy to adjust the parison length 8. Whole blow pin frame could be turned over onto top platform, convenient for mold change.9, Design is based at CE safety standard, concerning about user safety;10, Inverter is from Taiwan DELTA, adjust the screw speed, saving energy ;11, automatic lubrication system, automatic alarm function, more concerned about the user;12, Equipped with high temperature alarm function.MACHINE ADVANTAGES1. Toggle-balanced clamping frame, with well-known liner guide rail from Taiwan; great clamping force and explosion-proof;2. Can be achieved 16 blow pins at the same time perpendicular to the mold pin blow hole; patented die head, easy for changing color. 3. Computer intelligent control system, operation, set and modify the production process conveniently4. Deep mirror treatment is used inside the die head, curve flow channels are smooth, no dead ends, no carbon left;5. Strengthened and hardened cold treated screws, screw and barrel are with wear resistance; parts of tube wall thickness are very uniform6. Various components are produced with Japan's CNC machine tools, use Mazak to process six-sided installation surfaces at the same time. Imported well-known brands Hydraulic, pneumatic and electrical parts are equipped to ensure that the rigorous process, stable and reliable quality. Detailed Photos Product ParametersSpecification GS-12L-II Material PE,PP…Max. container capacity L12Number of die set1, 2, 3, 4,6Machine Dimensionm4.1×2.5×3Total weightton9.5Accumulator head GS-12L-II Number of die heatingzone3Power of die heatingKW6-7Max die -pin diametermm140Center distance of twin-diemm240Center distance of tri-diemm160Center distance of four-diemm120Center distance of six-diemm85Clamping Unit GS-12L-IIClamping forceKN110platen opening strokemm219-600platen size mm460×500Max mould sizemm560×500Mould thicknessmm220-380Extruder Unit GS-12L-II Screw diametermm80 or 90Screw L/D ratioL/D25Extruding VolumeKg/hr130-160Number of heating zonezone4Extruder heating power KW8.2-9.3Extruder driving powerKW37Power consumption GS-12L-II Oil pump drive powerKW15Fan power for screwKW0.6Total powerKW67Air pressureMpa0.6Air consumptionM3/min1.0Average energy consumptionKW35CertificationsPackaging & ShippingCompany ProfileGreat Supreme Industry Limited is an enterprise professionally manufactures HDPE blow moldingmachines, Injection machine and Plastic molds. We are devoting ourselves to technical research in order to build up a good reputation & famous brand. have already established business relations with more than 80 countries in Asian, Middle East, Africa, South America, European. There are departments special for machinery development and plastic molds development.foreign advanced technology and management system, under advantage of our solid technical power (professional engineers, large-scaled workshops, good design techniques), we are capable of having been developing different models of blow molding machine to supply the best quality products and service to the customers. High quality but reasonable price has been widely approved by our customers both in home and abroad. -Extrusion blow molding machine is for 50ml-200L PE/PP bottles, jerrycans, and drums. -Engineer is available to overseas for installation, commissioning, and short-term training. -All easy-wearing parts

Related products about Automatic Plastic 5L 10L Extrusion Blowing Blow Molding Moulding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup