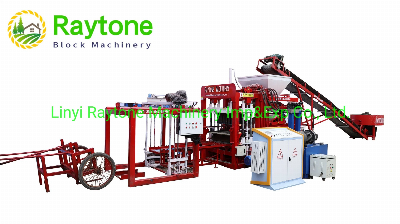

QT4-18 Simple Automatic Concrete Block Making MachineQT4-18 Block Making Machine Line QT4-18 simple automatic block making machine is a hot selling block machine line, it makes different blocks or bricks under different block moulds, the block mould is changeable, the block machine line is simple but automatic, its price is wallet-friendly, it is fit for middle and small investors for starting concrete block factory.QT4-18 brick machine Capacity: 6400 pieces of 8 inch hollow blocks per shift of 8 hours;Packing list of QT4-18 Automatic Block Machine full line1Q500 Pan Mixer1 set8JQ350 Pigment Mixer1 set26M Belt Conveyor1 set9Pigments Feeding Machine1 set3rick Pallet Feeder1 set10Blocks Stacking Machines1 set4QT4-18 Host Brick Machine1 set11Manual trolleys1 set5PLC control Pane1 set12Brick Pallet Loading Machine1 set6Hydraulic Station1 set13GMT brick pallet1000 pieces7Block conveyor Machine1 set14Spare parts1 setCapacity of different blocks models under QT4-18 Block Making Machine Production ProcessCompany Profile ExhibitionPackaging & ShippingFAQQ1:How to confirm what kind of block machines is fit for your project?A1:Normally there is two way to confirm what kind of block machine can meet your demand.As per the block productivity: Please tell the main blocks or bricks size that you mainly want to produce, and their daily productivity that you need. RAYTONE block machine manufacture can recommend you the right block machine model;As per budget limit; the client can tell us his budget limit, RAYTONE block machine manufacture will recommend as per the budget.Q2:What is the formula of raw materialsA2:The normal formula is cement-10%; sand-40%; stone-50%, water 5% per 100kg. But for different raw materials, the formula is a bit different, please contact us for more detailed formula information.Q3:What is the raw materials consumption per dayA3:As For QT4-18 Block machine line, take the 8 inch hollow blocks as sample, it needs 42 tons sands, 52 tons crushed stones, 10 tons cement, 4 tons water to make 6400 pieces of 8 inch hollow blocks;Q4:How long time does it take to take off block from the brick pallet?A4:The finished blocks can be take off from the brick pallet after 18-24 hours, then the brick pallet can be recycled for the block production; In some hot weather area, the blocks can be taken off from brick pallets after a few hours. The standard is the blocks are dry to be taken off is okay;Q5:What services can you provide?A15: Pre-sale (1) Professional suggestions. recommend the best machine according to the raw material, capacity and the size of brick (2) Answers to Clients questions online (3) Welcome to visit our factory and production line anytime. (4) Introduce the company , product categories and production process. In- Sale: (1) Update the production scheduling in time (2) Quality supervision (3) Product test and acceptance (4) delivery on time After-sale: (1) Online free technical installation guidance and paid on-site machine installation services (2)Engineer will help Set up, fix,and operate (3) offer training to the operator until they are satisfied at clients side. (4) Technical support the whole using life. (5) Recall clients regularly ,get feedback in time,keep well communication with eachQ6:Will you send engineer to install for user?A6: Yes, we have technician service team. and will supply machine installation service under payment.Q7: Are there any spare parts together with the machine ?A7:Yes, we will send spare parts together with machine, the user could use two years.Q8:Do you supply free technical service during later production ?A8:Yes, we have online technical service in 24hours.Q9: What is the Warranty for the machine?A9:For the machine,we have 1 years warranty (except the wearing part ).If any qualityQ10:Our advantages?Why choose us?A10:(1)Advanced technology improving system(2)High standard Quality Control(3)After-sale service for life(4)Professional Project solution (5)Affordable Competitive priceContact Us

Related products about Qt4-18 Automatic Cement Brick Hollow Concrete Block Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup