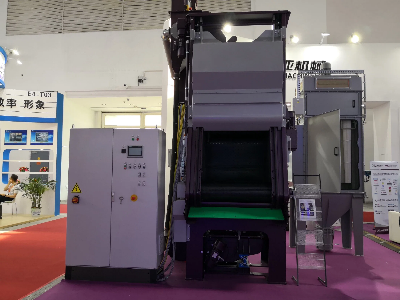

TAA brand Drum Type Shot Blast Machine blasting shot cleaning machine Product DescriptionRubber belt tumble blasting machineThe tumble blast design is widely accepted as one of the most efective blasting processes for removing scale, rust and burrs from mass production parts.The tumble blast machine's endless rubber belt gently rotates the work pieces and uniformly exposes them to the abrasive stream for the entire blasting time. Product ParametersTechnical SpecificationsMG 50MG90MG 180MG 270MG350 MG550Fill capacity (l)5090180270350550Belt dimensions φ x width in mm500*700600×800800×900800×1.35 1,000×1.350 1.200×1.200 Max.single work piece weight (kg)101015252525Max.weight of load(kg)1002004006008001000Work piece transportOptionalOptional Optional Optional Optional Optional Abrasive conveyor systemScrew Vibrating conveyor or screwVibrating conveyor or screwVibrating conveyor or screwVibrating conveyor or screwVibrating conveyor or screw Turbine (number x kw)1×5,5 1×7,5 1×7,51×7,5 1×112×7,5 2×11 2×11 2×18,5 2×11 2×18,5 Loader Optional Optional Optional Optional Optional Optional Filter unit PF 4/4 PF 4/4 PF 4/6 PF 4/9 PF 4/12 PF 4/12Our AdvantagesAdvantages of TAA rubber belt tumble blast machines1.Reliable blasting technology2.Innovative ilter technology3.Many diferent variants4.Automation through harmonisation with in-house transport system. Featurehigh-performance turbines Many different variants Automation 1.Our turbines are solid, well-constructed pieces of machinery. Due to a smaller number of wear parts and high abrasive throughput, they operate extremely economically.2.Because of the many different variants, it is possible to build the optimal blast machine for the intended application. Besides volume capacities of 50, 90, 180 and 270 litres, etc., users can also select the type of abrasive transport system and cleaning method. Conventional machines are equipped with a screw conveyor. TAA also ofers a vibrating conveyor for transporting abrasive as an available option. This option cleans the abrasive in the lower part of the machine ater the blasting process and then directly discharges impurities and any stray work pieces. Ater the blasting process, work pieces can be removed manually, or they can be fed directly to a work piece conveyor for further transport. This makes the machine easy to integrate into the industrial process.3.TAA MG machines can be optimally integrated with in- house logistics systems. Custom solutions using special containers have already been successfully implemented.The work pieces arrive at the loading mechanism in special containers (450 x 300 x 300 mm). The mechanism, which can be loaded from the side, takes the container and empties its contents into the blasting machine. Sensors auto matically control the loading process. The door of the blasting machine closes automatically and the blasting process begins. During this time, the loader returns to its initial position in order to pick up the next container of work pieces. After blasting, the work pieces move onto a conveyor belt. Waiting at the end of the belt is exactly the same container from which the parts were removed.Pressing a button on the control panel activates a loading mechanism that directly loads the blast machine. After the door is automatically closed and secured against accidental opening, the pre-defined blasting process begins. When the blasting process ends, the door opens automatically and work pieces are incrementally emptied directly into waiting containers. After Sales Service We place special value on perfect service. And not just for TAA shot blast machines but also for many other brands. Our service program includes: Wear and Spare Parts Repair and (remote) maintenance Inspection and advice Modernisation and performance enhancement Upgraded used machines Instruction and TrainingThe TAA distribution network consists of sales agents in many countries and regional sales partners in all important industrial regions. Company Profile ZIBO TAA METAL TECHNOLOGY CO., LTD is the leading manufacturer of blasting abrasives in China and one of the top third suppliers all over the world. Founded in 1997, TAA has been awarded as National Hi-Tech Enterprise, owning the only metal abrasive engineering technology research center in China. Relying on the research center,TAA has continuously developed many high-performance products more suitable for customers,including:low carbon bainite steel shot, low carbon bainite mixed abrasives, stainless steel cut wire shot, stainless steel grit etc. Certifications Our team TAA committed to the provision of high-end surface treatment equipment and solutions.It has finally realized the surface treatment industry chain from metal abrasives to surface treatment equipment and overall contractin

Related products about Taa Brand Rubber Belt Tumble Blasting Machine Shot Blast

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup