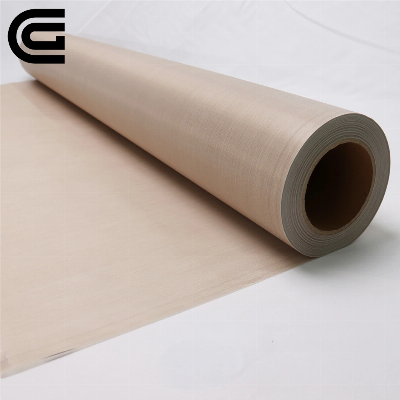

Porous PTFE Fabrics, porous release sheet for curing processPorous PTFE Fabrics has a high porosity than most PTFE coated fabrics, and this line combines fiberglass with lower levels of PTFE coating.This material is used in applications which need airflow throw the fabric under pressure (air circulation for drying and curing processes), normal applications including casting sheets for uncured elastomers, vacuum bag bleeder cloth for composite molding in the manufacturing of composite aircraft components.Unlike PTFE premium series, it is more flexible, much stronger and can be wrapped around curved shapes.Specifications:Base: Glass fiber fabricCoating: PTFEWidth: 1.27mThickness: 0.07mmFeatures:1. High temperature resistance, working from -70ºC~260ºC continuously2. High strength, elongation coefficient is less than 5%3. Porous and breathable, easy to remove after high temperature4. Corrosion resistance, aging resistanceApplications:* Aerospace, Communications & Milltary, Composite mold release in vacuum bag, or use as release sheets for fabricating glass-resin structures.* Polymer Processing: Manufacture of silicone rubber sheets, Curing rubber and plastic foams and sponge.* Insulation and protection.* Seperation materials.* Drying painted or lacquered products.* Release sheet for heat sealing machinesCompany profileEstablished in 2005, Taizhou Chenguang Plastic Industry Co., Ltd. is a high-tech enterprise specializing in R&D and production of materials.Our main products include PTFE film, PTFE adhesive tape, fluorinated ethylene FEP(F46)film and FEP adhesive tape. Our self-developed PTFE film tape with silicone adhesive specially designed for mold release of composite materials has been successfully put into mass production, and has been widely used in aerospace, chemical, environmental protection and other fields, which are widely acclaimed by users.Chenguang has a team of technical experts with over ten years of experience in the industry, dozens of PTFE coating and drying equipment, and high-precision turning film, blown film, cast film production and processing equipment, always organize production in strict accordance with the international quality control standards./* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about PTFE Fiber Glass Cloth Breathable Fabric

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup