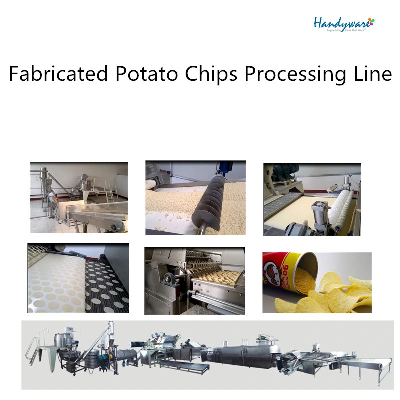

Company profile Handyware Engineering was established in 2003 and has a factory of 4,600 square meters at Foshan city. We design and develop for food snacks processing lines. Our mission is to fabricate processing lines that are easy to operate, high efficiency, low operaton cost and high product quanlity for our customers. we strive to continously innovate, regularly brining new creative products to our custormers. Hope our high quality products with competitive price can help broaden your market together. If have any inquiries or comments, please feel free to contact us. We would be glad to talk in details with you. Fabricated Potato Chips Processing LineTechnical information Dimensions(L*W*H)3900mm X 600mm X 430mmTotal Power100KWWeight25TElectricity Requirement380V/220V 50Hz/60Hz 3phaseDiesel Fuel15-30kg/hNatural Gas16-32 cubic meter per hourLPG8-13 cubic meter per hourOil Capacity(In Heat Exchanger & Pipes)950kgFrying Oil Refuel Rate56kg/hEnergy In Heat Exchanger450,000kcal/hourMaterialSS304Compressed Air Supply0.6-0.8MpaOperating ModeAutomaticEnd products Fabricated Potato ChipsOur strength1. Excellent end product Continuous, automated processing results in consistent, predictable end product2. Oil cost saving No oil discharge required if run 24/73. Top quality Manufactured using high quality stainless steel 3044. Productivity Labour 8-9 pax(exclude packing) Low oil wastage if run 24/7 Scrap dough recycled to reduce wastage5. Prevent Over-cooking Non-direct heating reduces oil rancidity Heat exchanger used to maintain desired cooking oil temperature6. High speed mixer Medical grade high speed mixer uniformly mix various raw material7. Recycle dough scrap Dough scrap recycled and mixed with fresh material Mixing achieved using enhanced mixer8. Cleaner oil Regularly circulated oil is filtered with 40 mesh filter9. Easy to control Central control panel to manage process parametersCustomer of Handyware Engineering ExhibitionPatent Certificate:Before sale services:1. Provide initial standard machine configurations. 2.According to the clients' special requirment,offer customized and competitively priced solution. Where necessary,offer customer with options . 3.Help client design the factory and offer professional advice ,provide free drawing for the factory layout.4.Welcome to visit our factory for machine viewing or trial. Services during the sales:1.Provide customer with regular production status update. 2. Invite customer for inspection of machine before delivery. After sale services:1.Oversea install of the equipment.2.Provide the basic food formulation.3.Operation/Service/Maintenance Manual: Provided in English.4. We will provide engineers to client's factory for the installation and training . The client is required to provide accomodation,food, round-trip ticket, visa,transportation fee and engineer fee of $80 /day/engineer.Design of capacity as per needs./* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Fabricated Potato Chip Processing Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup