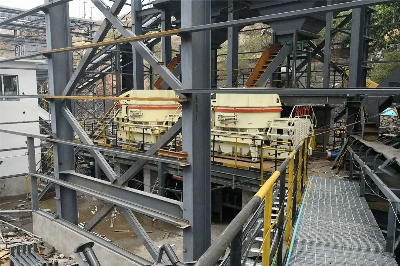

Product Brief Introduction6S new sand making machine is a crushing equipment with lower unit cost, higher crushing efficiency and intelligent operation control developed by our company based on the original high-performance VSI series and combined with the actual operation of the equipment under different working conditions and the feedback suggestions of the operator. By improving feeding mode, optimizing crushing chamber type, adopting new rotor design, adding lifting device and so on, the machine can significantly reduce the material flow resistance, improve the material passing capacity, reduce the wear rate of wearing parts, improve the energy utilization rate, prolong the maintenance cycle, shorten the maintenance time consumption. Now it has become a representative high performance crushing sand equipment in sand machine. Large capacity, high yield.Feeding mode is improved and easier to adjust; higher spindle speed and greater crushing chamber increased the machine's capacity in actual production.Lower consumption of wearing parts.The optimized crushing chamber makes the best impact angle and reduces friction of wear parts, which directly reduce the cost.Excellent particle shapeSelf-strike crushing principle enables the machine to produce the best particle-shape aggregates.It is easy to maintain because of hydraulic device. Hydraulic cover lifting device makes it's more convenient to inspect and maintain the crushing cavity's inner parts. Hydraulic lifting device and motor seat adjustment device can significantly reduce downtime.Automatic detection, it's being safe and reliable.The alarm device will give signals if the machine is dysfunctional, then the equipment stop to work quickly to protect the sand making machine. Working PrincipleMaterials are constantly conveyed to the stuff distributing plate of sand making machine and piled up. When crammed the chamber, the materials naturally fall into the hopper. After getting into the rotating impeller, they are accelerated by the high speed rotating impeller, and then shot through the tunnels around the impeller which can be 10 times of gravity acceleration. These materials in high speed crash with those in free falling (stone on stone), and then impact the plate that fixed on the whirlpool cavity (stone on iron). They will be rebounded and repeat the process again, thus the materials are constantly crushed. After impacted for several times in the whirlpool cavity, the crushed materials will be excluded through the bottom discharging hole. Technical Specifications Model6S-98326S-1245Capacity(T/H)Center and ring feeding450-520650-800Center feeding225-260325-400Max. feeding length(mm)Soft material

Related products about Advanced Technology Sand Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup