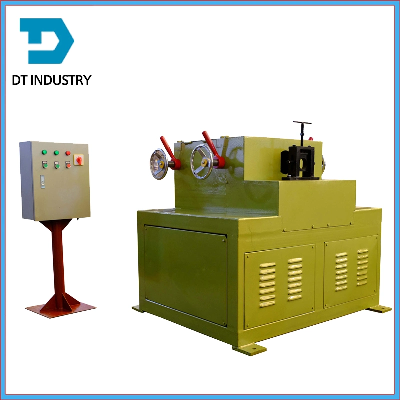

Product Description The straightening machine with rollers uses a set of pressure wheels that can adjust the distance to bend the metal bar up and down, and eliminate the stress of the metal bar in the process of bending, bending first and then pressing straight, so as to achieve the purpose of straightening the metal bar. In the process of straightening, the smaller the diameter of the straightened bar, the greater the degree of bending when straightening, the thicker the diameter of the straightening bar, the smaller the degree of bending when straightening. TWO ROLLERS STRAIGHTENING MACHINE for steel/copper/brass bar and pipe Numbers of rollers 2pcs (1 convex roller and 1 concave roller)Diameter of rollerOD160mm and working length 500mmSpecification6mm-16mmSpeed of straightening6-8m/minMain motor power4kw/4.5kwGear boxZQ250Center height750mmLength of bar2.5mWELCOME TO CUSTOMIZE Product ParametersNumbers of rollers 2pcs (1 convex roller and 1 concave roller)Diameter of rollerOD160mm and working length 500mmSpecification6mm-16mmSpeed of straightening6-8m/minMain motor power4kw/4.5kwGear boxZQ250Center height750mmLength of bar2.5m Related productsHorizontal straightening machine for round bar Horizontal and vertical straightener for hex bar steel/ brass Bar suface Peeling machine Two rollers vertical straightening machine Bar and pipe Polishing machine Bar and pipe shearing machineOur AdvantagesMaking a perfect proposal for your production line;Designing the suitable machines based on your requirements;Manufacture machines you need;Inspecting, packing, uploading and shipping service;Offering all related auxiliary machines, spare parts and consumable tools;Installing and adjusting machines on site and technology training your labors for operation;Trial production on site till everything is going well;On-site technology support if customer needs.24 hours service online before sales and after sales.Company ProfileGuangzhou DT Exp. & Imp. Co. Ltd is established in 2012. We are mainly manufacturing machines for non-ferrous metal production.The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.You may like /* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Two Rollers Metal Pipe and Bar Straightening Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup