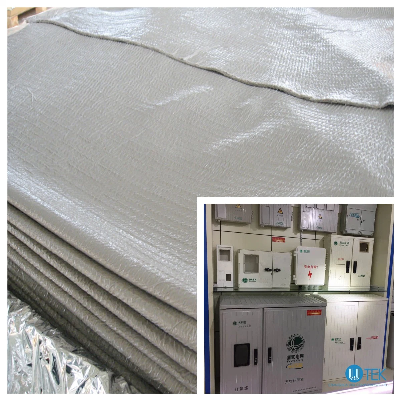

Product DescriptionSMC5342 is a sheet moulding compound based on unsaturated polyester resin. The product is glass fibre reinforced and contains mineral fillers. The material is compression moulded in heated steel moulds. It is recommended to work with chrome plated tools. It does not contain any halogens nor any candidates from the REACH SVHC list. General purpose SMC for electrical applications. Fire retardancy: UL 94, V-0 (3 mm) SMC5342 is produced in a standard width of 1000 mm. It is supplied on rolls holding up to 1500 kg. It is possible to have it folded and packed in cardboard/wooden crates. In any case a styrene barrier film wrapping is being used. For alternative packaging please contact our technical service team. Available in all colours. Product Parameters1. Features and main uses:5342-2 Pressed SMC sheet for automotive parts. The pressed product has the characteristics of extremely high mechanical strength, low shrinkage, no grinding, high heat distortion temperature and so on. Its performance is as follows: 2. Sheet performance:ItemUnitIndexTest MethodAppearance Uniform color, no discoloration impurities, good fiber impregnationHR B-80116 Area weightKg/m22.3-2.7HR D-61000Indentation hardness--100-500HR D-61000 The measured performance of pressed products:ItemUnitIndexTest MethodSpecific gravity--1.65-1.85GB/T1463Molding shrinkage%≤0.1HRD-61404Bending strengthMPa≥280GB/T1449Flexural modulus of elasticityGPa≥12.0GB/T1449Tensile strength MPa≥150.0GB/T1447Izod impact strengthKJ / m 2≥100.0Cantilever beamFlame retardant rating--V0UL94 3mmHeat distortion temperatureºC≥240GB/T1634 Recommended pressing process:Pressing time: In principle, the product thickness is about 1min per 1mm, which can be adjusted according to the actual situationPressing temperature: front side (bright side of product) / back side: 146-150 ºC / 138-142 ºC. (Note: This temperature is the mold surface temperature.)Molding pressure: higher than 100Kgf / cm 2. Storage conditions and shelf life:SMC should be sealed in aluminized film and stored in a cool and ventilated place below 25 ° C. Sheet storage period is two months from the date of production Related Product Safety Data (SDS):Before using this product, please be sure to read the SDS of this product. Detailed PhotosPacking photo Give us a chance, and we' ll return you with satisfaction. /* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Fire Retardant Sheet Molding/Moulding Compound SMC for Electrical Applications

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup