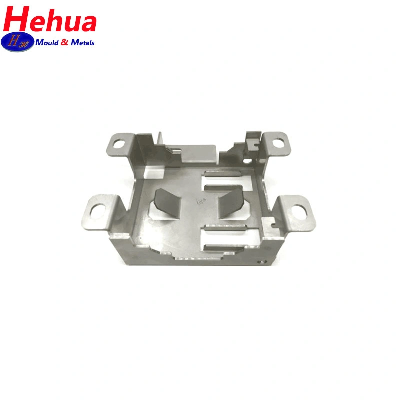

Company ProfileProduct Description:Product Name OEM High Precision CNC Metal Stamping PartsProduct DimensionVarious shapes are availableProduct ShapeVarious shapes are availableProcessing TypeCNC MachiningToleranceas per customers' requirement.Material Standard:ISO, DIN, ASTM, UNS, AISI, JIS, BS, NFMaterials availablesand casting, investment casting, die casting, permanent mold casting, forging, stamping, welding, and CNC machiningMaterial Thicknessas per customers' requirement.Surface Treatment/Finish Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Paint, Powder Coating, Polish etc.,Heat treatment capabilityAnnealing, Normalizing , Nitriding, Tempering ,CarbonitridingcapabilityCarburizing and induction hardening etc.,Industry Of UseUsed in metallurgy, automobile, aero, chemical, ship hardware, and other industriesQuality AssuranceISO 9001:2008, ISO/TS 16949:2009, RoHSSample Lead-timeWithin 1day for samples available from our stockAbout 1-2weeks for custom samplesMass Production Lead-time3-7 weeks after receiving deposit.Price Terms:EXW/FOB/CFR/CIF Shanghai or any other airport or seaport, ChinaPayment Terms30% deposit, balance against B/L copyModificationMould modification until the customers satisfy it.InspectionIn-house or third party, all the products are strictly inspected by skilled QCDesign:We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T)Country of OriginChina (mainland)Main Export MarketsEurope, America, Mid East, Asia, Africa etc.,Service Type:OEM & ODMBusiness Type:Manufacturer, ExportorAdvantagesExpert in producing OEM parts: metal stamped, machined, deep drawn and sheet metal formed parts with various finishingGeographical location advantage: our office in Shanghai which can help us to offer better services for the customers from all over the worldOur factory is located in Shanghai, nearby Shanghai ports, which can save transportation time and costEmploying reliable rockers and utilizing advanced machines: we have a full range of machinery and equipment for punching, welding, CNC, milling and grinding.We also have experienced technicist who are engaged in technical development. Our skilled workers, professional engineers, R and D center and excellent foreign trade team always keep the passion to support our customersAbout Us:Shanghai Hehua Mold Metal Co.,Ltd is an OEM manufacturing factory .Mainly produce the stamping parts,sheet metal parts,mold making ,spark-erosion wire cutting,CNC machining ,laser cutting and welding.our company own various equipments about 100,such as :Gantry milling ,Laser cutting ,Bending machine,Shearing machine,Punching machine 8T-200T,CNC Machining center,CNC Lathe machine,Milling machine ,Wire-electrode cutting ,Grinding machine ,Drilling machine,Threading machine ,Argon welder,Gas shielded welding machine ,Spot welding machine ,Squeeze riveter(Pressure riveting machine),Laser marking machine .Company has rich experience in mold design and excellent manufacturing capability, strict quality control system, for customers from product design, mould manufacture to the product production do unified service!And in August 2015 passed ISO9001:2008 quality certification system and TS16949:2009 certification system, our products are exported to Europe, America, Australia, Spain, Netherlands, Philippines, Italy, Japan and other countries, mainly client has saint-gobain, Germany continental, Faiveley, Ford, Mitsubishi, L&L , Tenneco and other well-known enterprises, for many years deep old customer recognition, on the basis of mutual benefit common development, to provide stable and reliable quality service to our customers.FAQ:1.what is your product range?CUSTOM machined/stamped/casting/extrusion/spring2.What about your sample policy?Simple sample,charge express fee only,complicated sample,will refund after place mass order3.What's your payment term?Sample: 100% before produce Batch:50% deposit 50% before shipping4.What kind of payment does your factory accept?T/T Paypal Western Union L/C5.What about the delivery time?Normal mold time: 10-12 days Machined parts: 3-5 days Batch: 10-15 days depend on quantit6.How about your after-service?Quality issue,If it is our fault,100% remake or as customer's requirement,if not our fault,try our best to give some discount to remake. /* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Manufacturer Batch Precision Hardware Parts Stamping Processing Custom Stamping Processing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup