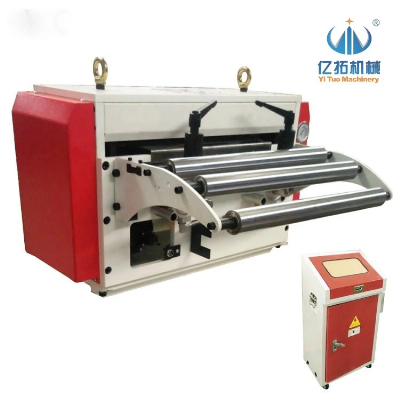

Product DescriptionFeatures of Roller Feeder1.This machine is suitable for the processing of symmetric alternative forms, which is used in the industries of motor blanking, aluminum wafer, kitchen and bathroom appliances lighting products, auto parts, stainless steel products, etc.2.Clear and clear picture direction, easy to operate. It has two relaxation methods: relaxation and relaxation, which can be used for different stamping processing.3.Suitable for extensive materials, mainly including steel,copper, aluminum, special alloy and bimetallic materials, and maximized the utilization efficiency of materials.Straightening capacity diagram1.This diagram is suitable for condition,which material stretch intensity is 40kgf/ mm.2. Straightening capacity may be change because of different actual condition.3. About coil outer diameter,material widthand deciliter standard load weight,pleaserefer to deciliter attachment diagram ofthis catalogue.4. About particular specification manufacturing, please contact us.Specification ModelNCF-200/NCR-200NCF-300/NCR-300NCF-400/NCR-400NCF-500/NCR-500Coil Width200 mm300 mm400 mm500 mmStrip Thickness0.2-2.5/0.6-3.5mm0.2-2.5/0.6-3.5 mm0.2-2.5/0.6-3.5mm0.2-2.5/0.6-3.5 mmFeed LengthMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmSpeedMax. 20m/minMax. 20m/minMax. 20m/minMax. 20m/minLine height44-136/44-114 mm44-136 /44-114mm44-136 /44-114mm44-136 /44-114mmSlacking style pneumatic pneumatic pneumatic pneumatic ModelJNC-200JNC-300JNC-400JNC-00Coil Width200 mm300 mm400 mm500 mmStrip Thickness0.2-2.2 mm0.2-2.2 mm0.2-2.2 mm0.2-2.2 mmFeed LengthMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmSpeedMax. 20m/minMax. 20m/minMax. 20m/minMax. 20m/minLine height44-136 mm44-136 mm44-136 mm44-136 mmReleaseMechanical Type Releasing SystemMechanical Type Releasing SystemMechanical Type Releasing SystemMechanical Type Releasing System ModelPNC-200PNC-500PNC-800PNC-1300Coil Width200 mm500 mm800 mm1300 mmStrip Thickness0.2-2.2/0.6-3.5 mm0.2-2.2/0.6-3.5 mm0.2-2.2/0.6-3.5 mm0.2-2.2/0.6-3.5 mmFeed LengthMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmMax. 9999.99 mmSpeedMax. 20m/minMax. 20m/minMax. 20m/minMax. 20m/minMax swing width200 mm500 mm800 mm1300 mmSlacking stylePneumaticPneumaticPneumaticPneumatic ModelRollerWidthFeedingLengthMaterialThicknessLineHeightPressCapacityDimensionsWeightABCDEFGMRFS-105NS100500-1.655-1005-205372472502922009529512064RFS-205NS200500-1.655-1002063734727034222012534512087RFS-305NS300500-1.655-10040737447270392220125345120103RFS-405NS400500-1.655-10060837547270442220125345120121RFS-505NS500500-1.655-10080937647310492220125345120141RFS-605NS600500-1.655-1001101037747410542220125345120161 ModelGCF-120GCF-250GCF-400Material width120mm 250mm400mmMaterial thickness0.35-1.0mm0.35-1.0mm0.35-1.0mmMaterial line thickness 60-120mm60-120mm60-120mmStandard partition quantity4/124/124/12Feedinglength0.15-199/5.0-0.66mm0.15-199/5.0-0.66mm0.15-199/5.0-0.66mmSkackening angle 135°-195° 135°-195° 135°-195°FeedinadirectionLeft→rightLeft→rightLeft→rightWeight237kg 267kg 320kg DETAILED IMAGES HOT PRODUCT Certifications COMPANY OVERVIEW PACKAGING LOADINGQ: Are you a factory or trading company?A: We are a factory which has been producing stamping automation machines for more than 20 years.Q: What's the delivery time? A: The standard machine is 25 to 30 working days after payment. For compact coil feed lines or whole metal stamping lines, it needs 30-70 workdays depends on different specifications and production plan in our factory,we will confirm the delivery time based on the specific project itself. Q: Do you receive OEM or ODM?A: Yes, we warmly welcome customers to do OEM and ODM in our factory.Q:What's warranty time of your machine?A:Usually the warranty time is 12 months. Also the warranty time can be extend acorrding the specific requirements.Q:What after-sales service does YITUO provide?A:For the standard decoiler straightener feeder machine, it's easy to install and debug it, most of our customers can do it by themselves; And what's more, our technical engineer can teach your operators how to install and operate it. For the compact coil feed machine and complete metal stamping line,YITUO can arrange engineers to go overseas for the coil handling equipment installation. They guide the customer's operators on-site.Q: What information you need to prepare the quotation:1. Coil thickness (min-max)2. Coil inner and outer diameter (min-max)3. What kind of your material4. Weight of your coils (max)5. How many tons you need per day or per month/* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Efficiency Automatic Coil Servo Feeder Machine for Metal Forging

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup