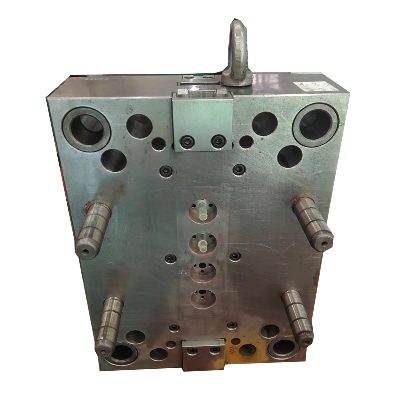

Product DescriptionName Custom made plastic parts Injection moulding Type of plastic mold 3-plate mold,2-plate mold Mold base LKM 50 standard mould base or Self-made Mold runner Hot/Cold Runner Base materialP20,P20H,718,718H,738,738H,2316,M300,S136,S136H,NAK80,CR12,CR12MOV,SKD11,DF-2,SKS3,D2,SLD,DC53,H13,SKD61,2344,8407,HD,8418,FDAC,M2,SKH-9 ,SKH-51,M35,M42,ASP23Mold Cavity 1*1,1+1,1*2,1+1+1,etc Diameter 5-1000mm,or customized Product Material ABS, PA, PA66+30GF, PBT, PC, POM, PP, PE, PMMA,PVC,TPE,TPU etc ColorWhite,black,green,nature,blue,yellow,etc Treatment S45C Pretreat>25Hrc,And Nitriding Inserts(cavity and core) H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required. Gate type Side gate,Sub gate,Pin point gate,Edge gate etc ShapeSheet, rod, tube, gear, pulley, guide rail, or as per your drawingEjection system Stripper plate,Lifter,Push bar,Ejection pin etc Design software Pro/E,UG,Catia,Woodwork,Moldflow,AutoCad Mold of steel suppliers FINKL,Assab,DAIDO,LKM,Buderus Hot Runners suppliers Synventive,YUDO,INCOE,HASCO,DME,MOLDMASTER,HRS,DELACHAUX,SINO Certification ISO9001,SGS,Test Report,RoHS Lifetime >300 Thousand Times Shipping Packing Wood case or carton box1. With plastic bag, with pearl-cotton package2. To be packed in cartons or wood case3. Use glass tape to seal cartons, or pin tight the wood case with nails.4. Deliver out by DHL, FEDEXOr according to the customer's requirement. Lead time of first samples Around 4~7weeks Other24 hours instant and comfortable customer service.Shipping status notification during delivery.Rhipping status notification during delivery. Detailed Photos Other ProductsProject Management ProcessHow to order from HOWE?1. Inquiry-Professional quotation.2. Confirm the price. lead time. artwork. payment term etc.3. Howe sales send the Proforma Invoice with Howe company seal.4. Customer make the payment for deposit and send us Bank receipt.5.Initial Production Stage-Inform the clients that we have got the payment and will make the samples according to your request, send you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time.6. Middle Production-send photos to show the production line which you can see your products in . Confirm the estimated delivery time again.7. End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party Inspection .8. Client make payment for balance and Howe ship the cargo. Also Howe can accept payment term-Balance against TT,Paypal or D/P payment Term.9. Order can be say "finish" when you receive the goods and satisfy with them .10. Feedback to Howe about Quality. Service. Market Feedback & Suggestion. And we can do better .Quality ControlHowe Mould Quality Control1.Mould Material Q/Ca) mould steel checking (hardness,flaw detection)b) mould spare parts checking (hardness,size)2.Mould Making Process Q/Ca) design checking ( part design,mould design,mould engineering drawing)b) mould size checking (according to drawing)c) mould testing (check mould working,sample Our Advantages1. We are a manufacturer specialized in OEM injection plastic parts from design to rapid prototype to mold to mass production for more than 10 years. 2. Long term cooperation with some Top Brand Auto Industry, such as Volvo. 3. We can assemble a complicated products. Providing samples with important dimensions and customizing inspection report material certification to customers for validation and verification. 4. Equipment includes CNC, EDM, grinding machine, injection machine (from 45ton to 1000ton), we can supply high precision and complex injection molds and products . 5. We offer unique solutions to your products at a competitive price and best service. 6. Strict quality control. The factory has the most advanced testing equipment to ensure the precision of the mold. 7. Your products will enter the supermarket, we can design a package for you.8. Quick mold making and on-time delivery. 9. We accept small order quantity, look forward to receiving your inquiry.10. Excellent R&D teams, Professional technicians and rich experienced workers 11. Providing good After-sale service, if the products have any quality problems, we will take charge of it. Company Profile Howe is a company specializing in the design and manufacture of high-quality plastic injection molds and injection molded parts for the international market and Have been engaged in the manufacturing sector since our inception.Is an OEM/ODM factory, customized your products to meet your needs is our advantage, We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed an excellent understanding of the technical and quality requirements needed. We build tools to fit your expectations and match your quality standards.Our team of CAD designers will ensure that your imagination

Related products about Custom CNC Machining Mould Maker for Plastic Injection Mold

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup