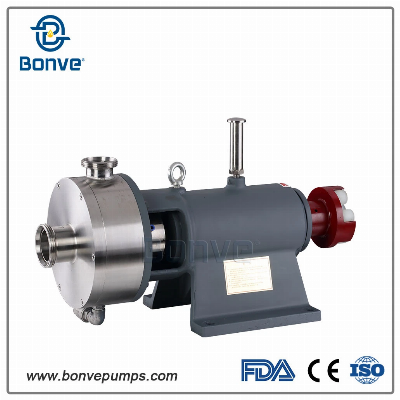

Inline high shear emulsifying and homogenizing mixer with CE Product DescriptionBonve high shear emulsifying and homogenizing mixer is a high-efficiency product integrating mixing, dispersing, crushing, dissolving, refining, depolymerizing, homogenizing and emulsification. After using this series of products, the original traditional production process is further simplified, the production efficiency is greatly improved, and the product quality is significantly improved. Homogenization is an important step in creating the high-quality products that consumers expect. The benefits include improved product taste, texture and consistency, which then translate into increased sales and customer satisfaction. Bonve homogenizer mixer are widely used in petrochemical, refinery chemistry, consumer chemicals, biology pharmaceutics, foods processing, paper-making, environmental protection, pain and so on.Features:100% dispersive shear;Quickly dissolves solids without agglomeration; No dead ends, high evenness;Time-saving, high-efficiency, low-consumption; Simple operation, convenient maintenance, and can realize automatic control.Working principleThe main parts are stators and rotors. At centrifugal and fluid forces created by high running of the rotors, the stators exercise on the materials with strong power shearing, centrifugal pressing, breaking, fluid friction, turbulent. The processed materials (solid, fluid and gas phase) are quickly refined, homogenized, dis-aggregated and emulsified. The repeat of this process can result in stable and high-quality products. Product lineBonve emulsifying and homogenizing shear pumps are mainly devided into 2 series based on different numbers of rotor and stator, working types. (The pump with 2-stage rotor and stage can be made as per request)FHM1 series with single stage rotor and statorFHM1 series is equipped with one set multi-layer stator and rotor. Required to be used in the cyclic processing of medium and small batch production. For short distance transmission, homogeneous and emulsion.FHM3 series with three stage rotors and statorsFHM3 series is an extension of the FHM1 series. The working chamber is composed of three-stage rotor and stator. For applications that require greater and quicker homogenizing and emulsifying, FHM3 is used. It can be used in the cyclic processing of medium and large-scale production.Product ParametersFHM1 seriesModelElectrical Power(Kw)Rotation Speed(r/min)Capacity(m3/h)Pressure(Mpa)Diameter of inlet/outletFHM1/1002.229000-30-0.05DN40/40FHM1/120429000-40-0.1DN40/40FHM1/1405.529000-50-0.1DN50/40FHM1/1657.529000-80-0.15DN50/40FHM1/1851529000-150-0.15DN65/50FHM1/2002229000-200-0.15DN80/65FHM1/2203029000-300-0.15DN80/65FHM1/2403729000-500-0.2DN100/80FHM3 seriesModelElectrical Power(Kw)Rotation Speed(r/min)Flow rate(m3/h)Discharge pressure(Mpa)Diameter of inlet/outletFHM3/1005.529000-30.1DN40/40FHM3/1207.529000-40.15DN40/40FHM3/1401129000-50.2DN50/40FHM3/16518.529000-100.3DN50/40FHM3/1853029000-200.4DN65/50FHM3/2004529000-300.5DN80/65FHM3/2205529000-400.5DN80/65FHM3/2409029000-600.6DN100/80Remarks: 1. Above dates are tested by water. For product with poor liquidity or require a higher discharge pressure, Bonve lobe pump is advised to be installed before the homogenizer for transferring.2. Port size can be changed as needed. Flange connection as starndard, clamp and thread as optional.3. Motor matched is Siemens, Siemens or equivalent brand. Normal type with 3ph/380V/50Hz as standard.4. MOC: SS304 as standard, SS316, 316L and others as optional. 150°C (302°F) anti-heat seal.5. Bonve reserves the right to change specifications without prior notification. DimensionsApplicationsTo selec a right model for your application, pls fill in the below table and send to us Your industry/application Processed medium's name Medium's feature Sanitary ( ) Corrosive ( ) Poisonous ( ) Medium's proportion Liquid % ____ Density____ Viscosity____ PH value____ Solid % ____ Solid size ___ Processing requirement Mixing dissolving ( ) Dispersed suspension ( ) Emulsification ( ) Homogeneity ( ) Reaction ( ) Powder liquid mixing ( ) Working type Continuous circulation work ( ) Continuous non-circulation work ( ) Batch type ( ) Working temperature Particle size Before processing _______ After processing ________ Handling capacity required Delivery head/pressure required Vessel's dimension Existing pipe size and connection type The existing process equipment and the existing problems About usBONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS, ISO9001:2015 approved company. Providing its customers with customized pumping and mixing solutions and solving their problems during the production. Bonve has more than 20 years of expertise and tec

Related products about Inline High Shear Emulsifying and Homogenizing Mixer with CE

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup