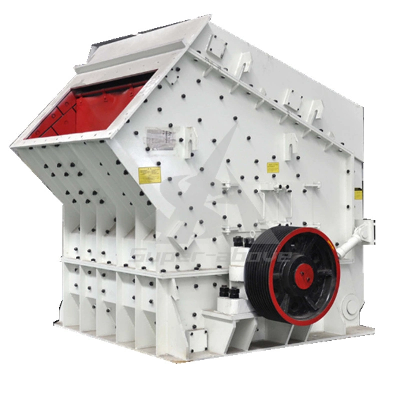

Brief introduction of impact crusher The PF product impact crusher is acknowledged in this field for a long time and gives smooth running resulting power economy and higher efficiency. Our stone crusher is mainly used to crush many kinds of large, medium, small materials such as rock or stone whose side length is less than 500mm, and compression resistance less than 350Mpa.It is widely used in hydroelectricity, highway, artificial rock, stone and sand, building material, etc.Working principle of impact crusherThis impact crusher machine crushes materials with impact force. When the materials enter the blow bar area, they are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor for secondary crush. Then the materials will be shot back to the blow bar again for the third crush. This process repeats until the materials are crushed to the required size and discharged from the lower part of the machine. The size and shape of the finished powder can be changed by adjusting the gap between the impact rack and rotor support.Applications of impact crusherImpact crusher is widely applied in mining, transportation, energy, construction and chemical industry. Impact breaking equipments are ideal choice for crushing and screening. This PF series stone crusher features reasonable structure, high productivity, easy operation and maintenance and safe performance.Technical Parameters of impact crusherModelrotor size(mm)Feed opening (mm)Max. feed size(mm)Capacity(t/h)Power(kw)Weight(T)PF-0607Φ644×740320×7301005-15304PF-0807Φ850×700400×73020010-25458PF-1007Φ1000×700400×73025025-4537-559.2PF-1008Φ1000×800400×83026030-5055-7510.5PF-1010Φ1000×1050400×108030050-8075-9014PF-1210Φ1250×1050400×108030070-120110-13217PF-1214Φ1250×1400400×1430300130-180132-18021PF-1315Φ1320×1500860×1520450160-250180-25025PF-1320Φ1320×2000860×2030500160-300300-37530Features of impact crusher1. The combination of multi crushing chambers can make the product in uniform particle sizes, which are suitable for crushing hard rocks. 2. The bottom impact plate structure makes the crushed products smaller in cubic shape with no internal cracks. 3. These series have big feed opening which is more easily for disposing production lines. 4. New type of high alloy abrasion materials makes the service life of blow bars, impact plates, and liner plates much longer. /* March 10, 2023 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Mining Equipment Fine Granite PF1214 Impact Crusher

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup