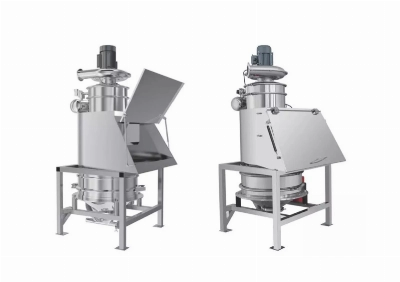

Working principle1. The automatic dust collection system can effectively absorb and discharge dust, prevent the generation of dust during the unpacking and feeding process of materials, and improve the working environment.2. A device can dump 50kg, 25kg, and 15kg bags to meet different processing requirements.3. A screening and vibration device has been installed to facilitate unloading and pipeline transportation, preventing foreign objects from entering the material during the feeding process.4. It is not easy to block materials, and dust collectors can also be selected to reduce dust flying, protect the environment, and reduce labor intensity.5. The bottom of the storage tank is equipped with an active hopper, which can be selected according to the size of the storage box as needed.Technical ParameterModelWT300Volume(L)300Power(KW)11.1 Compressed air consumption2/Pressure(L/min)/MPa50/0.6Discharge interfaceQuick installation 12 inchDust removal fan air outletDN150Weight(Kg)300Overall dimension(mm)L×W×H1300×1100×2000Product configurationCustomer SiteProduct Features1. Simple structure, extremely low equipment failure rate2. Low operational difficulty and fast onboarding3. Solve the problem of dust overflow, reduce environmental pollution and harm to human bodies4. It can be flexibly matched and customized according to customer conditions, requirements, etc5. Long service life, low maintenance costs, and extremely high cost-effectivenessCommon troubleshootingWhen there is a malfunction in the dust-free feeding station, please check according to the following procedure first:Fault phenomenonFault causeTroubleshootingNo backflushingThe compressed air valve is not openOpen the compressed air valvePulse valve malfunctionCheck pulse valveFilter cloggedReplacing the filter elementNo electric vibrationDamaged vibration motorReplace the vibration motorThe vibration motor is not powered onConnect the power supply to the vibration motorSlow or no fan extractionFan damageReplacing the fanFilter cloggedReplacing the filter elementIf the fault cannot be eliminated after following the processing methods listed in the above table. Please contact our sales personnel in a timely manner so that we can quickly diagnose the cause and troubleshoot the problem for you.Application IndustryDust free feeding stationProduct application scope: food industry, pharmaceutical industry, metallurgy and mining industry, chemical industryMaterials: essence, monosodium glutamate, adsorbent, catalyst, graphite, rouge, powder blusher, polyethylene, polypropylene, polyoxyethylene, fertilizer, veterinary medicine, feed, premix, additives, laundry powder, salt, monosodium glutamate, chicken essence, white sugar, seeds.Customer Reference /* January 22, 2024 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Small Bags Emptying Equipments Sacks & Bag Opening Machines

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup