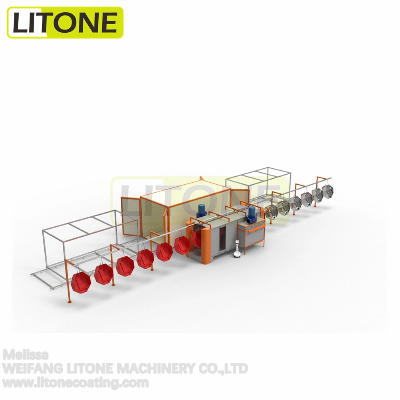

Manual Powder Coating System Powder Coating Machine Spray Booth Curing OvenProduct DescriptionPowder coating line is to automatically coat the surface of the product to attach their favorite color or decoration to replace the labor force by automatic coating. The powder coating line designed and developed by our company has fast scoating speed, uniform coating, high efficiency, low energy consumption, and can increase the output; the up and down conveying system has developed an auxiliary down automatic leveling device for the difference between long and short materials, and the process is controlled fully automatically. Powder coating machine (Powder coating production line) for metal sheet/furniturePowder coating line with conveyor system forheavy industryWe specialize in the whole line:1) Pre-treatment system: Automatic coating pre-treatment and dipping pre-treatment are available;2) Drying oven: Drying oven which drying the water after pre-treatment is designed according to customers' actual conditions.3) Powder coating system: Automatic coat reciprocator, manual coat equipment and Semi-auto (Auto-coatng with manual repairing coating) are for your choice;4) Powder recycling system: Cyclone equipment and cartridge filters is customized and introduced according to actual requirement by customer;5) Curing oven: Tunnel curing oven, bridge type curing oven, Electric power heating curing oven, Gas-heating curing oven, Diesel heating curing oven, High temperature, lower temperature curing oven is available for fitting your sole factory.6) Conveying system: Various design according to different requirement by customer on the basis of customers' workpiece and output information.7) Control system: PLC control, with or without touch screen8) Spray gun and reciprocator Production namePowder coating painting production lineCoating LineAutomatic coating line / Manual coating line / Semi paint spraying line / Electrostatic powder coating booth etc.Conveyor SystemChain conveyor, Belt conveyor, Plate conveyor, Overhead conveyor and Power and free conveyor are all available according to the clients' requirementsCoating OvensDrying oven and curing oven with various heating energy, like gas, electricity, diesel etcCoating MachinesElectrostatic powder coating gun; Airless paint sprayer etcControl SystemSiemens PLC control system(optional), Customized design etc.Warranty1 year after the installation of production line is completed After sale serviceOn-site installation, on line and on-site problem shooting ApplicationPowder Coating Machine for Metal surface.Powder Coating Machine for Car wheel.Powder Coating Machine for Bicycle frame.Powder Coating Machine for Aerospace Area.Powder Coating Machine for Fitness Equipment.Powder Coating Machine for Track Traffic.Powder Coating Machine for Medical Devices.Powder Coating Machine for Petroleum Pipes, Valve. Our Service1. Purchase ServiceOurs Coating has a specialized and efficiency working team. If you are new on the coating, that some pictures or drawings of your products and workshop shown to us will be appreciated, we will give you specialized suggestion of whole work.2. Shipping ServiceOurs Coating has a specialized and independent department for shipping the buyer's goods. The workers know T/T, L/C terms well. All Exported documents could be made perfectly. We cooperate with the most famous shipping company in China also. They could provide the best and economic shipping ways to the buyer's port.3. Installation ServiceInstallation Service is available with all our machines. Ours Coating will dispatch technicians to the Buyer's factory to install and trial operate the equipment.4. Clients' Training ServiceOurs Coating can accept that the buyer arranges their own technicians to our factory to learn how to operate machines. Also, training in the installation period is better acceptable.5. After Sales ServiceOurs Coating will provide one year warranty period. Many spare parts will be prepared in the tool box together with machines.Company ProfileEatablished in 2013, Weifang Litone powder coating machine Ltd is a manufacturer specilized in reseach. Development and production of powder coating machine and other spare parts. We are located in Weifang, China, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a varity of different markets throughout the world.We are professional in the powder coating system and liquid painting system. The Powder coating system includes the powder booth, after-filter, cyclone, sieving machine, hopper, powder coating machine/unit, manual electrostatic powder coating gun, aotomatic electrostatic powder coating gun, cascade, PCB, gun injector/pump, powder hose, filter and other parts; The Liquid paint system includes the water-screen booth, cup, electrostatic liquid painting gun, air gun, diaphragm pump, constant voltage valve, pneumatic parts and so on. In addition,

Related products about Manual Powder Coating System Powder Coating Machine Spray Booth Curing Oven

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup