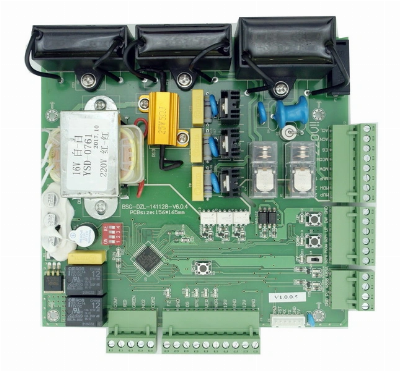

Jingxin PCBA Electronic TechnologyShenzhen Jingxin Electronic Technology Co., Ltd. is a professional enterprise dedicating to PCB and PCBA manufacturing for 20 years, providing professional OEM electronic manufacturing services for customers in various fields around the world. Since its establishment in 2002, the company has accumulated a group of engineers with more than ten years of manufacturing experience and professional electronic components purchasing team. With ten years of professional spirit, providing professional engineering services (PCB layout design, SMT process technology solutions, etc.) → PCB manufacturing → electronic components purchase → supply chain management → PCBA manufacturing (SMT and DIP) → one stop integrated manufacturing service from test, maintenance, aging test and assembly to directional development.Our more than 800 employees are proud to serve customers in various fields including aerospace, medical equipment, industrial automatic control, new energy, automotive electronics, wearable device, 5G communication, drone and LED display, etc.More than 1500 customers have witnessed our growth over the past 20 years, the company is located in building 13 and 17 Hongfa Industrial Park, Tangtou Road, Bao'an District, Shenzhen. We have 10000 square meters of dust-free workshop and more than 800 employees, more than 30 production lines including PCB manufacturing, SMT, DIP, automatic welding, aging test and assembly etc. The equipment includes over 50 SMT machines from Japan and Korea, automatic solder paste printing machine, automatic stencil test machine, automatic stencil cleaning machine, automatic first sample test machine, SPI solder paste on-line detector, 12 temperature reflow soldering machine, on-line AOI detector, X-ray detector, lead-free wave soldering machine, automatic DIP machine, automatic PCB splitting machine, laser carving machine, automatic coating machine, automatic X-ray counting machine, intelligent MES electronic material management system etc., with a daily output of 40 million points. A variety of production line configuration can meet all kinds of demands from sample order (lead time 24-hours) to mass production delivery. Key Specifications/ Special Features: Term:Detailed Specification of PCBA Board Manufacturing Layer:1-30 layer Material:FR-4, CEM-1, CEM-3, Height TG, FR4 Halogen Free, FR-1, FR-2, Aluminum Board thickness:0.4mm-4mm Max.finished board side:1020mm*1000mm Min.drilled hole size:0.25mm Min.line width:0.10mm(4mil) Min.line spaceing:0.10mm(4mil) Surface finish/treatment:HASL/HASL lead free,Chemical tin,Chemical Gold,Immersion gold Inmersion Silver/Gold,Osp,Gold Plating Copper thickness:1/2OZ 1OZ 2OZ 3OZ Solder mask:colorgreen/black/white/red/blue/yellow Inner packing:Vacuum packing,Plastic bag Outer packing:Standard carton packing Hole tolerance:PTH:±0.076,NTPH:±0.05 Certificate:ISO9001,ISO14001,ROHS,CQC Profiling Punching:Routing,V-CUT, Beveling Assembly Service:Providing OEM service to all sorts of printed circuit board assembly View of Jingxin Electronic PCBA Assembly1) Professional Surface-mounting and Through-hole soldering Technology2) Various sizes like 1206,0805,0603 components SMT technology3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.4) PCBA Assembly With CE,FCC,Rohs Approval5) Nitrogen gas reflow soldering technology for SMT.6) High Standard SMT&Solder Assembly Line7) High density interconnected board placement technology capacity. Quick-turn Prototyping:Fast-turn around 24 hours electronic print circuit board prototype Quick prototype turnkey electronic print circuit board Assembly within 7 days High end Manufacturer: Rigid, Flex,Rigid-Flex, HDI, Metal Core, 10-40 layers etc. On-Demand FabricationStrong Supply Chain Management:Consist of wide qualified distributor and huge selection in-stock. Components are ready to Ship or Assembly100,000+ Parts In-stock components2000m² Component Warehouse800+ Qualified suppliers and vendors50+ Experts Procurement Team20+ sec Instant Result7,000,000+ Parts Real-time Stock & PricePrototyping (Quick-turn available)Standard electronic print circuit board 1-10 layers FR4 · Originalbuild time 72h + shipping time 48h · Urgentbuild time 48h + shipping time 48h · ExtraUrgentbuild time 24h + shipping time 24h Advanced electronic print circuit board (10-40 layers, HDI etc.) · Originalbuild time 10-12 Days +shipping time 48hVolume Production ·Small volume & Middle volume · Competitive Price · Min. Board Thickness 0.2mm · Min. Trace/Spacing 3.5mil ·Quick-turn AvailableFull-service Turnkey electronic print circuit board Assembly Solution electronic print circuit board manufacturing,components sourcing and in-house assembly, whole project managementavailable Key Specifications/ Special Features: Term:Detailed Specification of PCBA Board Manufacturing Layer:1-30 layer Material:FR-4, CEM-1, CEM-3, Height TG, FR4 Halogen Free, FR-1, FR-2, Aluminum Board thickness:0.4mm-4mm Max.finished board

Related products about Robot Vacuum Cleaner PCB and PCBA Assembly

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup