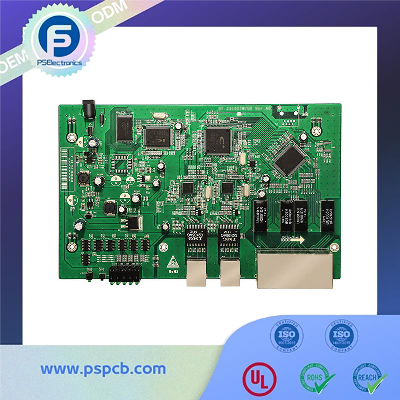

PCB ParametersItemPCB ParametersMaterialFR4 (140Tg, 170Tg, 180Tg), FR-406, FR-408, 370HR, IT180A, Metal Core, Polyimide, Rogers 4350B/3003/4003C/5880, Taconic, Teflon, etcMaterial BrandsKB, ITEQ, SY, ISOLA, Rogers (Arlon), Ventec, Laird, Nelco, Bergquist, DENKA, Panasonic, Taconic, or other laminate on customer's requestLayer Count1-40FlammailityUL 94V-0Thermal Conductivity0.3W-300W/mkQuality StandardsIPC Classes 2/3HDI Build-upAny Layer, up to 3+N+3Board Thickness0.2~7mmMin Thickness2-layer: 0.2mm4-layer: 0.4mm6-layer: 0.6mm8-layer: 0.8mm10-layer: 1mmMore than 10 layers: 0.5*Layer Count*0.2mmCopper Thickness0.5-20ozInksSuper White Inks/Solar/Carbon InksSolder Mask Thickness0.2mil-1.6milSurface FinishesBare Copper, Hasl lead-free, ENIG, ENEPIG, Gold Fingers, OSP, IAg, ISn, etcPlating ThicknessHASL:Copper Thickness: 20-35um Tin: 5-20 umImmersion Gold:Nickel: 100u"-200u" Gold: 2u" -4u"Hard Plated Gold:Nickel: 100u"-200u" Gold: 4u"-8u"Golden Finger:Nickel: 100u"-200u" Gold: 5u"-15u"Immersion Silver: 6u"-12u"OSP: Film 8u"-20u"Min Hole Size0.15mmMin Trace Width/Spacing2mil/2milVia Plugging0.2~0.8mmLine Width/Space Tolerance±10%Board Thickness Tolerance±5%Hole Diameter Tolerance±0.05mmHole Location Tolerance±2milLayer to Layer Registration2milS/M Registration1milAspect Ratio10:01Blind Vias Aspect Ratio1:01Outline Tolerance±0.1mmV- CUT Tolerance±10miBevel Edge± 5milWarp and Twist≤0.50% (max cap)Quality TestAOI, 100% E-testValue-Added ServicesDFM Check, Expedited ProductionFeatured ProcessesBonding, Impedance Control, Via in Pad, Press Fit Hole, Countersink/Counterbore Hole, Castellated Vias, Edge Plating, Peelable Solder Mask, Resin Plugged, Plating FlatData FormatsGerber, DXF, PCBdoc, ODB++, HPGL, BRD, etc PCBA AbilitiesItemPCBA AbilitiesTurnkey Service PCB Design + PCB FAB + Components Sourcing + PCB Assembly + Package Value-Added ServicesBOM Analysis, Conformal Coating, IC Programming, Wire Harness & Cable Assembly, Box Building Assembly Details 5 SMT + 2 DIP (Dust and anti-static lines) Assembly AbilitiesSMT 5 million points per dayDIP 10 thousands pieces per day Technical Support Free DFM/A check, BOM analysis Handing Standards IPC-A-600H, IPC-A-610F, J-STD-001FMOQ 1 piece Inspection & Testing Visual Inspection, AOI, SPI, X-ray inspection. First article inspection for each process. IQC + IPQC + FQC + OQC Inspection Flow Flying probe test/In-circuit test/Function test/Burn-in test Files We Need PCB: Gerber (CAM, PCB, PCBDOC) Components: Bill of Material (BOM list) Assembly: Pick-and-Place file Functional test: Test Guide PCB Panel Size Min: 0.25×0.25 inches (6×6mm) Max: 20×20 inches (500×500mm) PCB Solder Type Water soluble solder paste, RoHS lead-freePCB Assemble MethodsSMT, THT & Hybrid, single or double side placement, Part removal and replacement. Components Details Passive down to 0201 (01005) size Press fit connectors QFP/BGA/LGA/QFN/COB/COF CSP/WLCSP/POP Fine Pitch High Pin Count Connectors BGA repair and reball Lead Time Prototype: 5-15 working days; Mass production: 20~25 working days. The fastest delivery time is 3 days. Packaging Anti-Static Bags/Customized Packaging One-Stop OEM PCB Assembly Professional Turnkey PCBA COMPANY PROFILESPinsheng Electronics started to provide contract electronics design and manufacturing services in 2008, we are obsessed with providing the happiest manufacturing experience to our customers.When our founders found it difficult to get technical support and always high-quality products from the manufacturers, they sprouted the vision to provide blissful electronics manufacturing services to others, they rented an old workshop and started the journey.In over 15 years, with the same vision, we have designed, manufactured, and delivered 5,000+ projects for over 2,000 SMEs. The products are alive to us, not lifeless pieces of stuff.Main CustomersProcessCasesUnderwater Lighting·High thermal conductivity·Thermoelectric separation·0.15mm Inner core·Micro bump etching·0.1mm Between FR4 and copperIndustrial BMS·4-Layer PCB·6OZ Inner layer copper·Edge plating·High current designEV Charger PileTurnkey PCB assembly for control board of EV charger pile.Medical Equipment·Large area of ENIG·Custom red soldermask·6-Layer rigid-flex boardCommunication Equipment·6-Layer rigid-flex board·10% Differential impedance·Ventec PPV447·ShengYi FR4·DuPont laminatedPCB Showcase PCBA Showcase SMT & DIP WorkshopQuality And Policy:Continually improve our quality, efficiency, service to satisfy thecustomer's requirement.Quality System:1. ISO-9001:2018 Quality System Standard2. ISO14001 Environment System Standard3. Quality Standard: IPC-610-D class 2,4. Soldering Standard: J-STD-001 class 1,2,35. ESD Standard: ESD-MIL-STD-16866. Workshop management:5S7. FAI-first article inspection 8. In process visual inspection9. AOI inspection10. X-ray Inspection11. SPI Inspection12. Machine calibration and preventative maintenance13. ERP material and process management ( ERP=enterprise resource planning compute

Related products about PS One Stop Service Customized PCB PCB Assembly Industrial Control PCBA

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup