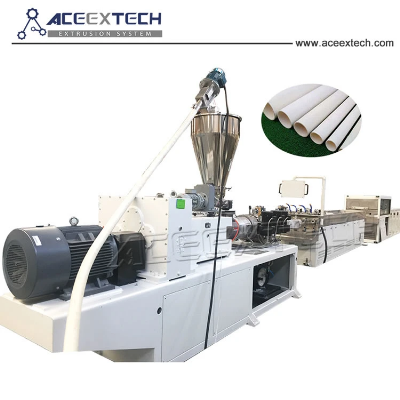

PVC water pipe extrusion lineApplication:PVC Plastic pipe making machine is mainly used in the production of Agricultural water supply & water discharge system, architectural water supply & discharge system, wire laying system, etc. purposes. The unit consists of Conical (Parallel) double screw extruder-PVC pipe mold-Vacuum forming tank-Haul-off machine-Cutting machine-Stacker/Belling machine. Producing pipe diameter range: Φ16mm-Φ630mm.And the line can be equipped with Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.Advantages:1. Specified screw design for better material plasticizing &mixing effect, For high filling formula, bimetallic screw and barrel can guarantee perfect solution;2. Spider type die head can reduce joint line of the melt material, with reasonable compression ratio design;3. Vertical integrated structured gear box with adopts NSK/SKF bearings guarantee stable operation and long uselife;4. Vacuum calibration tank adopts high-efficiency two chamber and large length design, providing faster calibration and more efficient cooling;5. Planetary cutter adopts hydraulic feeding of blade which providing perfect chamfering processing and cutting surface;6. U type, R type and Air blow type socket can be provided according to applications;7. Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently.Work flow and detailed information :Feeder- To feed material into extruder;Extruder- World famous brand electrical component such as Siemens,Schneider, ABB etc;- High torque gearbox with adopts NSK/SKF bearing;- Siemens/WEG original motor achieved global after service;- Bimetallic screw and barrel;- Intelligent PLC controlling system with human-friendly interface. Die head - High melt homogenity- Low pressure built up even with high outputs- Melt channel distribution system- Equipped with seramic heaters- Pipe head carriage for easy movement- Easy maintenance thanks to the optimized and proven designed construction.Vacuum calibration tank- 304 stainless steel with painted outer surface- Special water sprays are located on the best position for cooling the pipe efficiently- Special and easy adjusted pipe supports for each pipe diameter- Installed vacuum and water pumps can work without any maintenance for long times- Special cooling baths can be designed for specific extrusion productionHaul off- Upper and lower caterpillar is driven separately by the frequency inverter- Fast change type padsPlanetary cutter- Automatic synchronisation with extrusion speed- Planetary equipped with disk and milling cutter for cut and chamfering- Touch screen control panel- User friendly software developed by Aceextech- All movements are motorised and controlled by control panel- Pipe blocking vices device- Type of the cutting unit is chose depend on pipe.- Less maintenance needs.- Completely closed and secured machine for maximum safety.Belling machine- Socket forming: smooth (solvent cemented)- Socket forming: shaped for insertion of rubber gasket (blowing system)- Socket forming: collapsible system- Socket forming: auto-load rubber gasket- Touch screen control panel- User friendly software developed- Automatic synchronisation with extrusion speed- Pneumatic, hydraulic and motorized movements.- High quality belling tools.Stacker- Stainless steel 304 as touching material- Discharge driving by air cylinderTechnical Parameter:Diameter ranges(mm)Extruder modelMax. Capacity(kg/h)Max. lineal speed(m/min)Extruder motor power(kw)16-32 (4-cavities)ACE65/13230010*43720-63 (Dual)ACE65/13230015*23750-160ACE65/13230083775-250ACE80/156500655110-315ACE80/15650045575-160 (Dual)ACE92/1888506110315-630ACE92/1888501.2110 Technical Parameter of Main extruder:ModelPower(kw)Screw Diameter (mm)Screw Qty.Designed Output (kg/h)Dimension(L*W*H)(mm)ACE-45/9015Φ45/902703360x1290x2127ACE-51/10518.5Φ51/10521003360x1290x2127ACE-55/11022Φ55/11021503620x1050x2157ACE-65/13237Φ65/13223003715x1520x2450ACE-80/15655Φ80/15624004750x1550x2460ACE-92/188110Φ92/18827506725x1550x2814 Main components: - Motor: Siemens, WEG, SEW- Gear reducer: SEW, FALK- Bearing: SKF, FAG, NSK- Air cylinder: Festo, SMC, AirTac- PLC interface and module: Siemens, Schneider, Beckhoff- Frequency inverter: ABB, Schneider, Siemens- Servo motor: Lenze, Delta- Pressure sensor: Dynisco, Gefran- Low voltage component: Siemens, Schneider, Omron, LS- Temperature controller: Omron, RKC- Solid state relay: Crydom, CelducAbout ACEEXTECH:ACEEXTECH is a creative company, focusing on R & D of plastic extrusion system, and providing the equipments and solutions for plastic pipe, profile, tile, sheet and board.ACEEXTECH products fulfill the needs of users in a very direct way due to over 25 years of knowledge and experience in plastic extrusion field, which also helps us to contribute actively to the success of customers by offering sustainable solutions that meet industry

Related products about PVC Water Pipe Extrusion Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup