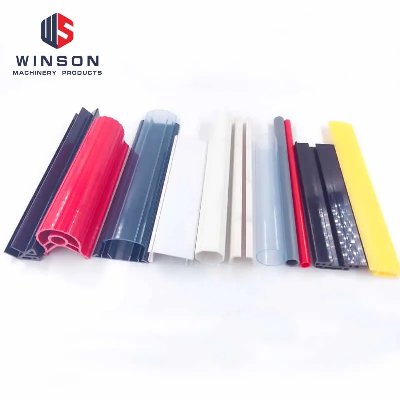

Winson Plastics is a well-established company providing an extensive selection of high quality extuded plastic profiles. We are a trusted and experienced supplier with a commitment to creating cost-effective and durable products with consistent results every time. Our extrusion services are designed to meet the specific needs of customers and can accommodate a wide range of requirements including custom designs and shapes. We use the latest technology to create the most precise profiles and shapes while ensuring superior strength and performance. All of our products are stringently tested to guarantee top quality standards. You can trust Winson Plastics for unbeatable reliability and exceptional services.Functions & Applications of Plastic ExtrusionUsing plastic extrusion, Dalilai can craft superior products for use in a variety of industries. Our plastic extrusion processes allow us to make products for automobile, construction, medical, electronic and optical industries. Plastic extrusion is useful for creating tubes, bars, hoses, rods, sheets, profiled and co-extruded products, food and beverage applications, and much more.Plastic extrusion can be used to create a broad array of products from items such as medical tubing and conduit, to more advanced items like window frames, packaging materials and filaments. Our team can make custom profiles to meet the exact specifications for your product. As a top name in plastic extrusion, Dalilai has the experience and expertise to bring your ideas to life.Plastic Extrusion ProcessAt Dalilai, we specialize in plastic extrusion and specialize in providing superior results with excellence and precision. The plastic extrusion process has four main steps:Feeding: The plastic material is fed into the machine in the form of small pellets. This is done using a special feeder system that is calibrated to the right speed for the material. This is the most important stage of the process, as getting the correct speed and orientation of the plastic is paramount for quality output.Heating: As the plastic passes through the machine, it is heated to the optimal temperature for extrusion. This is important for ensuring that the plastic flows correctly and also that it will cure correctly when it is molded.Extruding: The extruder will then pressurize the heated plastic, forcing it through the extrusion die. This die determines the shape of the final product. The process is carefully controlled to ensure uniformity and accuracy in shape and size.Cooling: Once the extruded plastic has formed the desired shape, it must be cooled so that it will cure correctly and maintain its shape. The cooling process is important in ensuring the plastic will form correctly and will not warp or deform.Materials We Work WithMaterialCommonly Used forPolyvinylchloride (PVC)Pipes, hose, window frames, cable insulation, blister packsAcrylonitrile Butadiene Styrene (ABS)Appliance housings, hose plumbing systems, refrigerator linersPolyurethane (PU, TPU,HPPE)Seals, gaskets, buffers , conveyor belts, hose tubing, fuel lines, toysCross-Linked Polyethylene (PE,TPE)Insulation, conduit, water and gas pipes, electrical wire, roofingPolytetrafluoroethylene (PTFE)Non-stick cookware, valves, gaskets, bearings, tapesPolystyrene (PS)Food packaging, plastic utensils, foam coffee cupsThermoplastic Elastomer (TPE)Shoe soles, toys, gaskets, seals, adhesivesPolypropylene (PP)Food containers, brushes, carpets, auto parts, laboratory equipmentAcrylic (PMMA)Eyeglass lenses, signs, window glazing, aquariumsWhy choose us to produce your plastic extusion profiles?1, Low price - Professional manufacturers with independent sales , no middlemen earn profit.2, High quality - From the raw material procurement, production management, product testing and other key links to ensure strict control of product quality and win customers trust.3, Rich experiences provide convenient technical communication.4, Short mold opening cycle and high production efficiency.5, Special services such as silk screen printing, water transfer printing, thermal transfer printing, surface embossing, etc.6, No worries after-sales, we adhere to the "integrity cooperation, mutual benefit and win-win" purpose, to provide customers with a full range of services./* January 22, 2024 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Plastic Profiles Extrusion, PVC ABS PP PE PU Extuded Plastic Profiles

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup