Guangdong Fenghua Zhuoli Technology Co., Ltd (FHZL) is one of China's earliest companies engaging in researching 3D printing technology and commercialize the technology. The company successfully developed the advanced technology based on the 3D sand printing and applies the technology into China's foundry industry. FHZL has grown into a comprehensive high-tech company that could offer complete R&D & manufacturing, sales of 3D sand printing equipment, 3D printing complex metal parts, 3D printing combined with gravity and low pressure casting of traditional metal mold, CNC precision machining, customization of rapid manufacturing for 3D sand mold (core) printing, application of 3D data processing and 3D digital integrated technology, various 3D printing consumables, etc. The cold core (box) manufacturing technology for 3D printing of micro-droplet jet sand mold was first developed in China, acquired multiple patent certification, this unique technology is superior and compatible with the conventional process. It would greatly changes the conventional production cycle and manufacturing technology in foundry industry.FHZL has more than ten years of rapid casting & processing experience, over 1000 different types of product development cases per year, provided rapid manufacturing services to nearly 400 large enterprises both domestic and abroad which were widely used in automotive, pump, valve, machinery, mining machinery, construction machinery, vessel, aviation, aerospace, new energy, rail transit, casting mold and many other industries.Why work with FHZL?FHZL brand and reputation: The national High-tech Enterprise in China; The foundry Industry Association in Guangdong Province; The 5A Association of Automobile Industry in Foshan City; The listed company on stock market(stock code:834914). Strict quality control system: Included incoming inspection, sample inspection, process inspection and delivery inspection. IFAT 16949 certificate, CE certificate and ISO 14001 and ISO 9001 certificated factory. Lower cost and shortened delivery time: patented new technology PCM (patternless casting manufacturing) has been applied to our manufacturing which improved the traditional casting efficiency rapidly. No need of mold, casting pattern be formed one time, save the mold cost and mold making time. More flexible during process: In case of any failure on the design, PCM technology just need to modify the 3D drawings and restart, no mold modification cost. What's the technical process for casting?High precision CNC machines and inspection devices. Our Advantages(1) Competitive price, all products are casted and machined in our factory, shipped directly to customer. (2) Reliable quality, IATF16946 certified casting manufacturer, we have strict control about quality. (3) Professional, we focus on production of Auto Parts for more than ten years. (4) Fast shipment, we have a efficient management system, several automatic casting lines, and more than ten machining lines. (5) Excellent service, our sales team has more than ten years' experience in oversea market, we know you better. (6) Flexible production, we can customize the product according to your drawing. FAQ1. Are you a factory or trading company? We are a IATF16949 certified factory specializing in producing Auto parts. We cast and machine the parts for more than ten years. 2. Can you customize the parts according to the drawing? We have professional technical dept., we are able to customize your parts according to the drawings. 3. Can you supply samples? We can supply the samples, but you need to bear the development and delivery cost. 4. Do you have a min order quantity? We don't have a min order quantity, we can send you the parts according to your drawings 5. What is the period of sample production? It will take 15~25 days to develop new product.ItemCustomized Precision CNC Machining PartsMaterial1.Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. 2.Steel Alloy:l: Carbon Steel / Die Steel / Spring Steel etc. 3.Brass Alloy: 3602 / 2604 / H59 / H62 / etc. 4.Bronze:C51000, C52100,C54400 etc 5.Iron: 1213, 12L14,1215 etc 6.Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / ADC12/518 etc.Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium etc.Surface treamentAnodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc.Tolerance±0.08mmEquipmentCNC centre,CNC lathe,General lathe,General Milling, CNC milling, Drilling machine, internal grinder.Cylindrical grinder machine,centerless grinder machine & other equipments.StandardOur factory are specialized in the production of Non-standard products. We also could produce standard productsInspection toolMicrometer, Thread Gages,Calipers,Pin Gauge,Projector,CMM, Altimeter etcQuality control1. Quality control :The defective products rate is 0.1%. Imported material 100%.2. Reasonable price , Precision made.Experience & Reasonable QC th

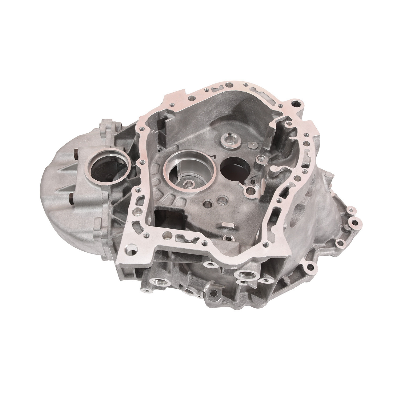

Related products about Machined Parts Customized Casting Part New Energy Vehicles Parts Motor Housing

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup